Poly Pipe Electrofusion Fittings

What is Poly Electrofusion?

Electrofusion is an electrical fusion process by which an external sleeve fitting incorporating an element is installed to poly pipe or fittings and with

The current applied to the fitting is regulated and supplied by an electrofusion welding machine, which controls the amount of voltage, amps and welding time supplied to a fitting, in order for it to weld strongly and permanently.

The electrofusion process

Why Use Electro Fusion?

With correct training and preparation equipment Electrofusion permits a safe, effective and efficient fully welded installation for both buried and above ground poly piping systems. Electrofusion products are separately sealed in PE bags and packaged in cartons to protect them from UV radiation, oxidation as well as general contamination. Additionally, they are provided with a bar-coded label that contains all relevant product information,

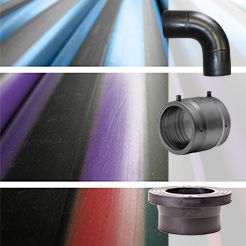

Our Extensive range of poly electrofusion fittings available

Other types of electrofusion couplings are available, such as reducers (or reducing couplings), equal and reducing tees and elbows in both 45 and 90 degrees,

allowing virtually any assembly or manifold to be site-fabricated when exact dimensions are not known. Couplings are available in both high pressure and low-pressure applications. To the right is an image of an electrofusion elbow which is available in both 45 and 90 degrees, to allow for changes of direction and offsets.

Electrofusion branch saddles and tapping saddles are also available, making

the system very adaptable, especially when you're cutting into an existing pipeline. To the left is an image of an EF tapping saddle. The biggest benefit of the electrofusion tapping saddles is the ability of them to be welded into a live pipeline, reducing downtime, or "shut-down" time, and

ELECTROFUSION WELDING

Welding machines are required for welding electrofusion sockets. The transportable welding machine, connected to a power source, provides a current source of the Welding machines and rotary scraping tools are required for welding

Poly electrofusion welders vary in size and capacity. The particular welding machine pictured (on the left) is a Ritmo Elektra 315, which welds most electro-fusion brands available on the market but is limited in capacity up to 315mm diameter. There are other sizes available, to suit 1000mm and above if required. Poly electrofusion welding can be operated off both mains power and generator power. We have a company policy of not promoting welding machines that are brand specific, so you can take our guarantee with confidence that our welders will suit most fittings on the market.

ELECTROFUSION TRAINING

We highly recommend that all personnel that will perform electrofusion welding be trained to PIPA standards. Speak to our friendly staff about your electrofusion training requirements.

Below is a demonstration of a large bore electro-fusion weld being performed with a Ritmo Elektra 1000 welding machine in Italy. Please note: recommended installation methods vary from country to country and the methods used in this video are not all endorsed in Australia.

Enquiring about our poly pipe electrofusion fittings

Sales + Customer Service:

Head Office:

5 Richards Rd Swan Hill Victoria 3585

Melbourne Despatch:

2 Richards Circuit, Keilor Park Victoria 3042

(by appointment only)